Producing high quality compost

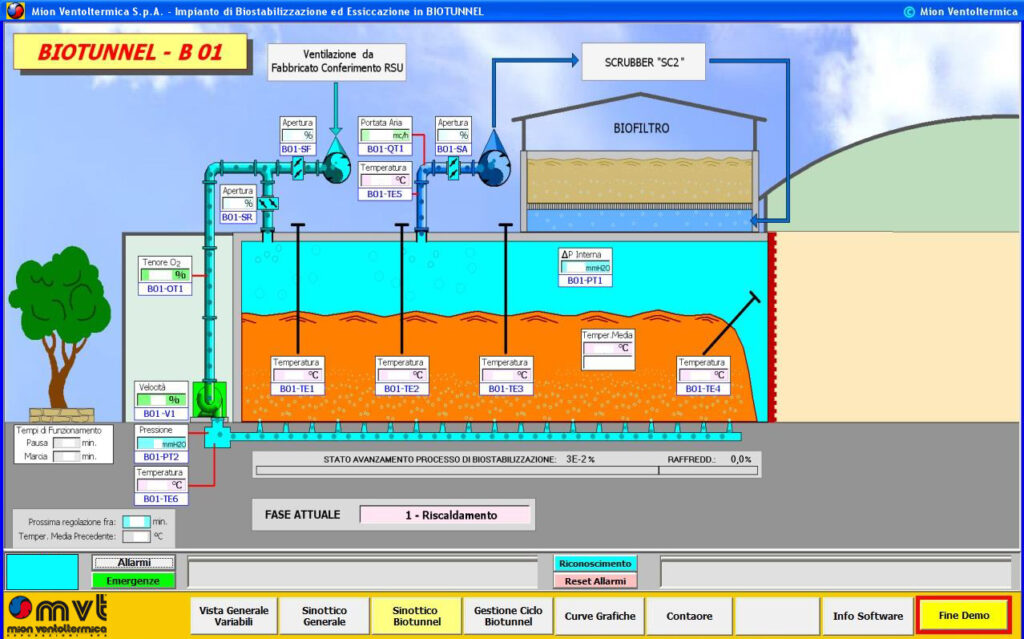

Compost production is based on transforming organic waste (food scraps, grass cuttings, trimmings, etc.) from differentiated waste collection, using an aerobic biological process, which consists of placing the material inside special structures equipped with aerated floors, which can keep the material in perfect aerobic conditions and bio-oxidise it.

Parameters such as temperature, humidity and oxygen concentration are checked constantly, and in real time, so as to speed up the normal waste maturation process and obtain the biologically inert material, rich in nutrients.

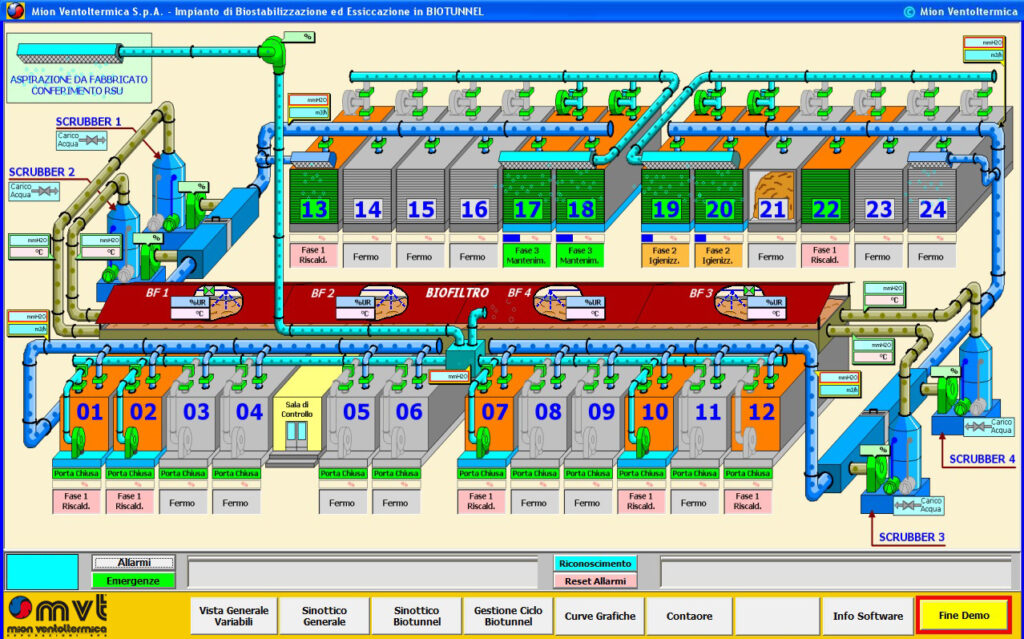

All bad-smelling air produced is sucked up by fans and treated effectively and efficiently by scrubbers and a biofilter, produced by us so as to have working environments that are healthier and safer.

Mion Ventoltermica has been designing, building and installing automated and technologically-advanced composting systems (aerobic biostabilization) for many years, aimed at meeting customers’ specific needs in the most efficient way.